Stripping off the elastic bandage after about 18 hrs revealed very little glue residue and that all cleaned up quickly with a cloth and some warm water. The glue line isn't as clean as when it came from the factory, but doesn't look terrible either. I was happy to see that the paint breakaway at the body joint had glued back almost imperceptively.

I glued the nut back on with a small amount of Titebond and left for a few hours. Reconstruction complete 😀.

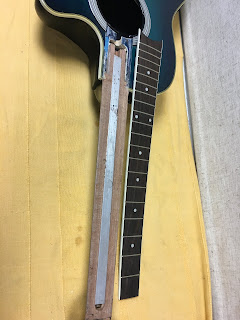

Strung up with a new set of D'Addario strings, I could then give the truss rod a tweak to take the very slight bend out of it. The picture doesn't really show this well, but it's pretty much ruler straight now.

All done and it plays quite nicely (for a budget guitar!). It's certainly much easier to play than before the repair. As I said in the intro, the sound is pretty weedy, due to the nature of the ABS back and sides. It will be interesting to hear it through an amp. All ready to go to a beginner guitarist I have in mind now.

Summary & Lessons Learned:

This has been probably the scariest job I've done to date and yet proved to be pretty straightforward really.

I am really delighted that I took the route of repairing the truss rod rather than buy a new one. The whole project cost me less than £10 including glue etc and is probably a better end result than if I'd bought a new rod.

I've already mentioned that I should have scored the paint between the body and fingerboard extension, which would have prevented the paint flaking away. I was lucky that this glued back OK - it could have been a lot worse.

Also, when I glued up the fingerboard, I should have clamped the joint at the nut end more rigidly. There wasn't quite enough pressure from the elastic at that point and the joint lifted very slightly; not enough to affect the structural integrity or playability, but it would look better. I'll make a couple of specific clamps for this on the next job.

Other than that, I'm really pleased with how this went. I understand how a truss rod works now and feel totally up for attacking the Faith fingerboard now to resolve the iffy neck repair.

Watch this space....